Watching video tutorials by third parties, as well as the materials on the official SketchUp website and their YouTube channel, I managed to model along in their browser-based application, which is free to use, and created random items I had in my house to learn the techniques required to model something I could actually use, before moving onto the motivation behind learning all this.

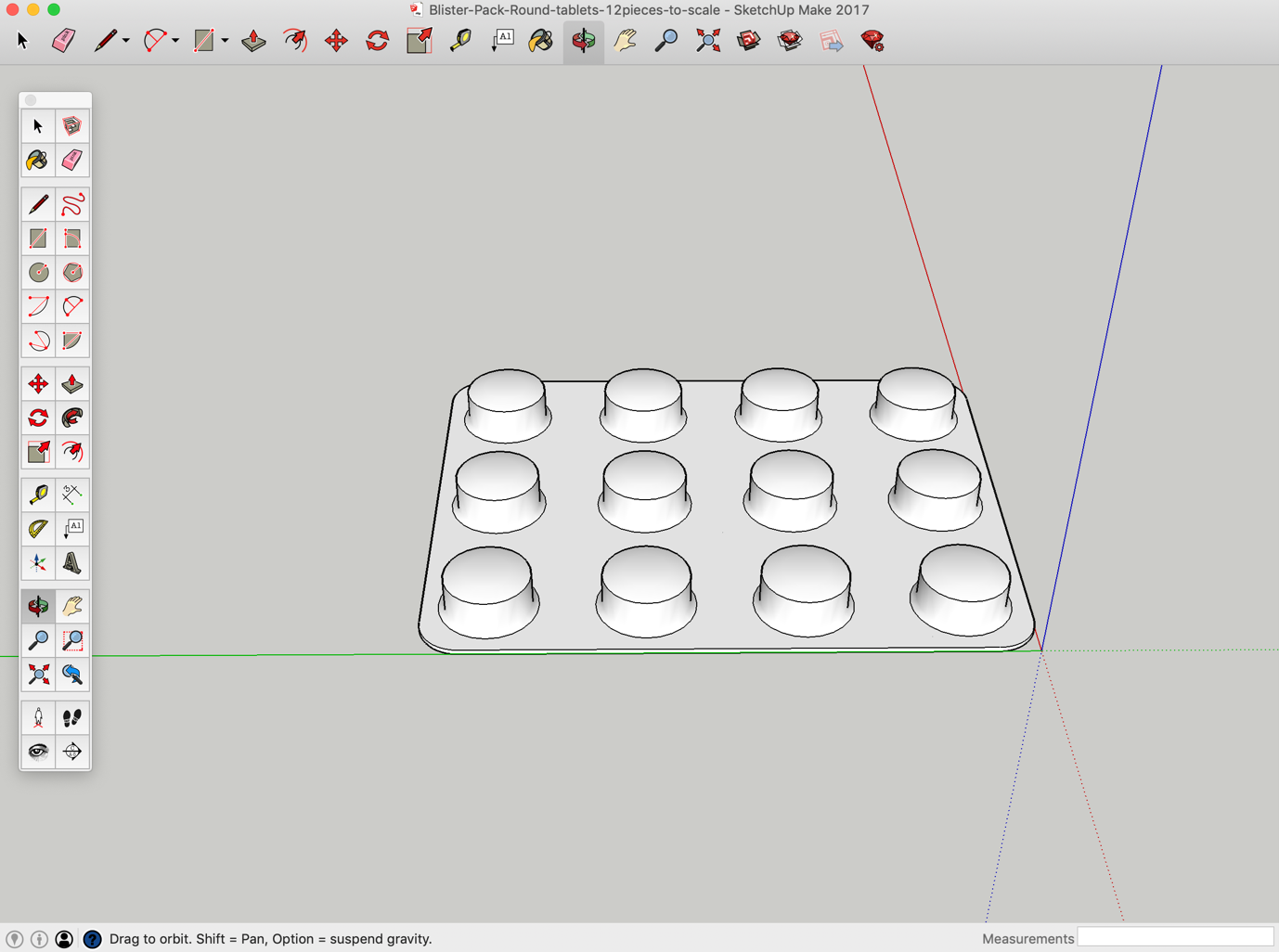

Project #1: Blister pack

Acetaminophen, non-steroidal inflammatory drugs, antihistamines and many others come in various types of blister packaging and are useful for adding realism to scenarios (and is not particularly complex to model, even for a beginner like me), with the added advantage that they are cleanable, disposable in regular household waste and that replacements are cheap, even if the printing is outsourced.

Source: SketchUp

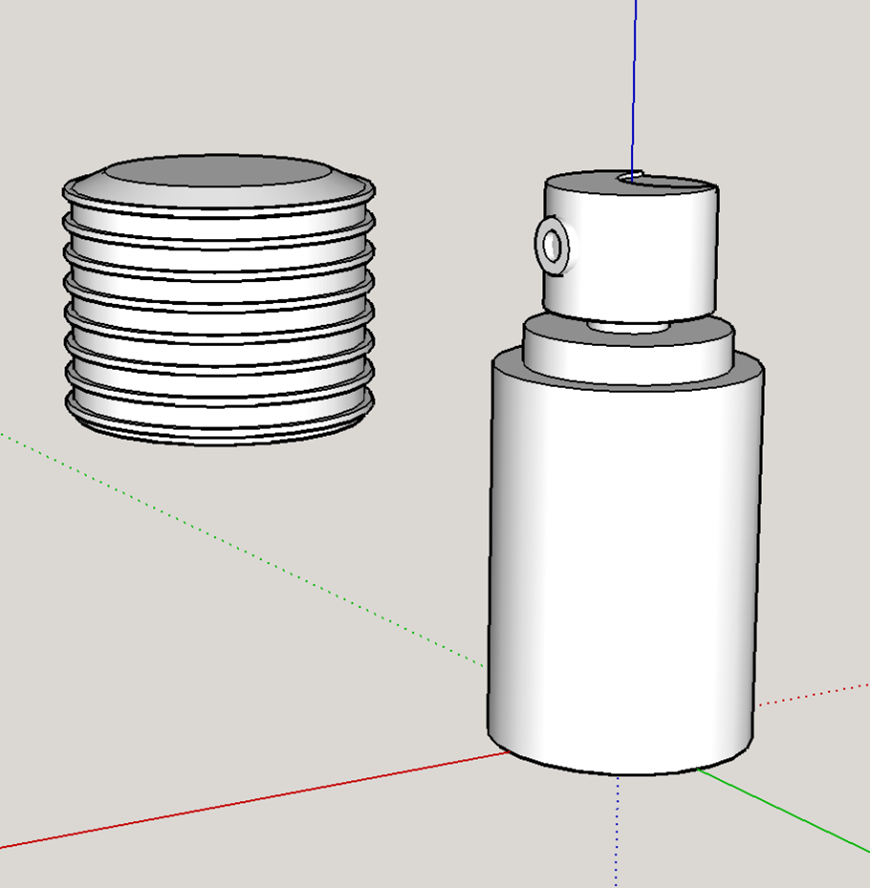

Project #2: Glyceryl-trinitrate sub-lingual spray

GTN (glyceryl-trinitrate) spray is widely used in patients suffering from angina, forms part of the drug box for Paramedics, EMTs, and many other healthcare professionals and is part of many scenarios and medical histories worldwide.

Source: SketchUp

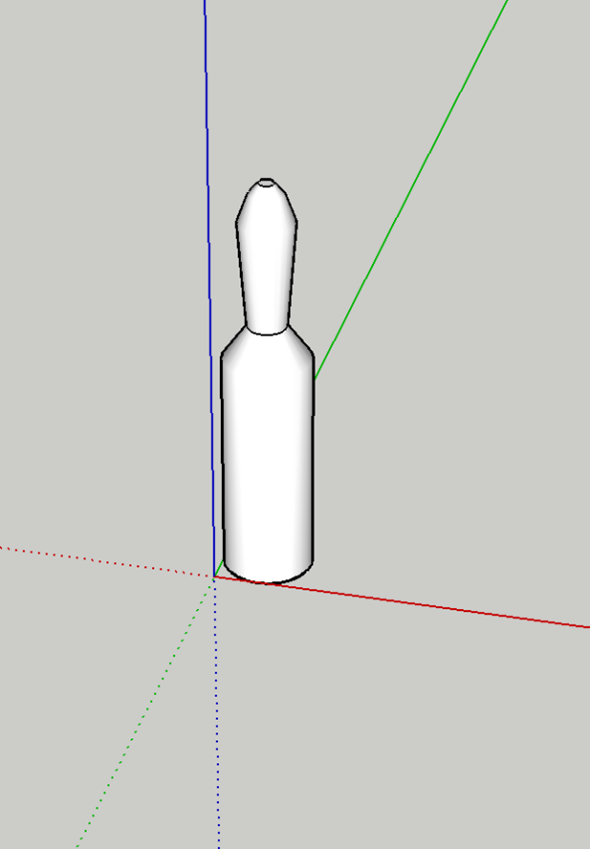

Project #3: Drug ampule (e.g. epinephrine 1mg in 1ml)

Drug ampules for displays, scenarios or training purposes where drug administration is not physically required, these make a great alternative to glass ampoules, as there is no risk of injury, having to keep track of medication and no concerns over what type of “medication” can be left out in plain sight. Morphine sulphate or other opioids can be replaced with these placeholder ampules. All that is required is a set of labels to identify them as training drugs, their dosage, and expiration date, and all is ready to go.

3D printing the models

Printers and printing materials vary, depending on what features are desired, such as size of the printable volume, area of application, production cost per part and type of material the printer can use. The most affordable printers on the market typically print with a filament called PLA (polylactic acid), a corn-starch-based product that is molten and then layered onto a so-called “build platform”. It is non-toxic, comes in a variety of colours and is useful for a large range of projects, while allowing it to be printed on even the most basic of 3D printers. Project #1 was printed with white PLA and took about 50 minutes to print.

.jpg)

Self-printed vs. paying for 3D printing

PLA printing is very affordable. Each of the projects shown cost between $1 and $5 in material, if printed on your own printer. Having it commercially printed by a third party is more expensive, but a great choice if purchasing a 3D printer is not currently desired or affordable. These companies tend to have a minimum order value, however, meaning that you cannot order one ampoule on its own without paying a surcharge.

Other Printable Medical Equipment

3D printed objects are not limited to prototypes, props, accessories and product testing. There are projects available online that aim to address a challenge in the world of healthcare, sometimes supported by evidence and original research.

Stethoscope: In 2018 a paper published in PLOSONE explored a 3D printed stethoscope that can be made for around $15 and has shown comparable to the well-known Littmann Cardiology III made by 3M. The paper shares its design process, plans and performance testing. The files and instructions for making your own can be found on a portal called thingiverse.com, as well as on other 3D forums and platforms online.

Video laryngoscope: Airway management with the aid of video laryngoscopy has grown in popularity in recent years, but the cost of equipment is high, thereby making training a costly exercise as well. A company called Air Angel has created, designed and tested a 3D printed video laryngoscope that can be used in combination with an Android smartphone and connected endoscope style camera (non-medical grade) or a stand-alone video endoscope (non-medical grade) that can be purchased online at an affordable price. It is important to note that this is not an FDA approved medical device, i.e. not intended for patient use, but as a training tool. However, it is undoubtedly a great way to introduce healthcare providers to this technology without the need to spend thousands of Dollars/Pounds/Euros.

The beauty of 3D printing is the community involvement in upgrades, improvements and alterations to existing designs. The original Air Angel blade was edited by a user on thingiverse.com and consequently adopted by the original designers as it had improved their original design.

3D printing is used in more industries every year and is no longer limited to PLA, but already includes liquid resin printing and even metals. Their affordability has grown significantly, not only creating many new brands and features to choose from, but also a thriving second-hand market, as well as adoption by many companies and universities, giving access to this technology to a much wider audience.